Belmont Chapel @belmontchapelfoundation in Newport, RI, has undergone a stunning restoration after years of vandalism and disrepair. In 2023, they engaged us to create four replicas of their lost angel windows. All we had to work with were the few remaining shards from the originals, which included broken pieces of a face, wings, cross pieces and a small portion of the original blue background. When we look now at the “before” and “after”, it seems so straightforward. But there was so much that we learned in the process.

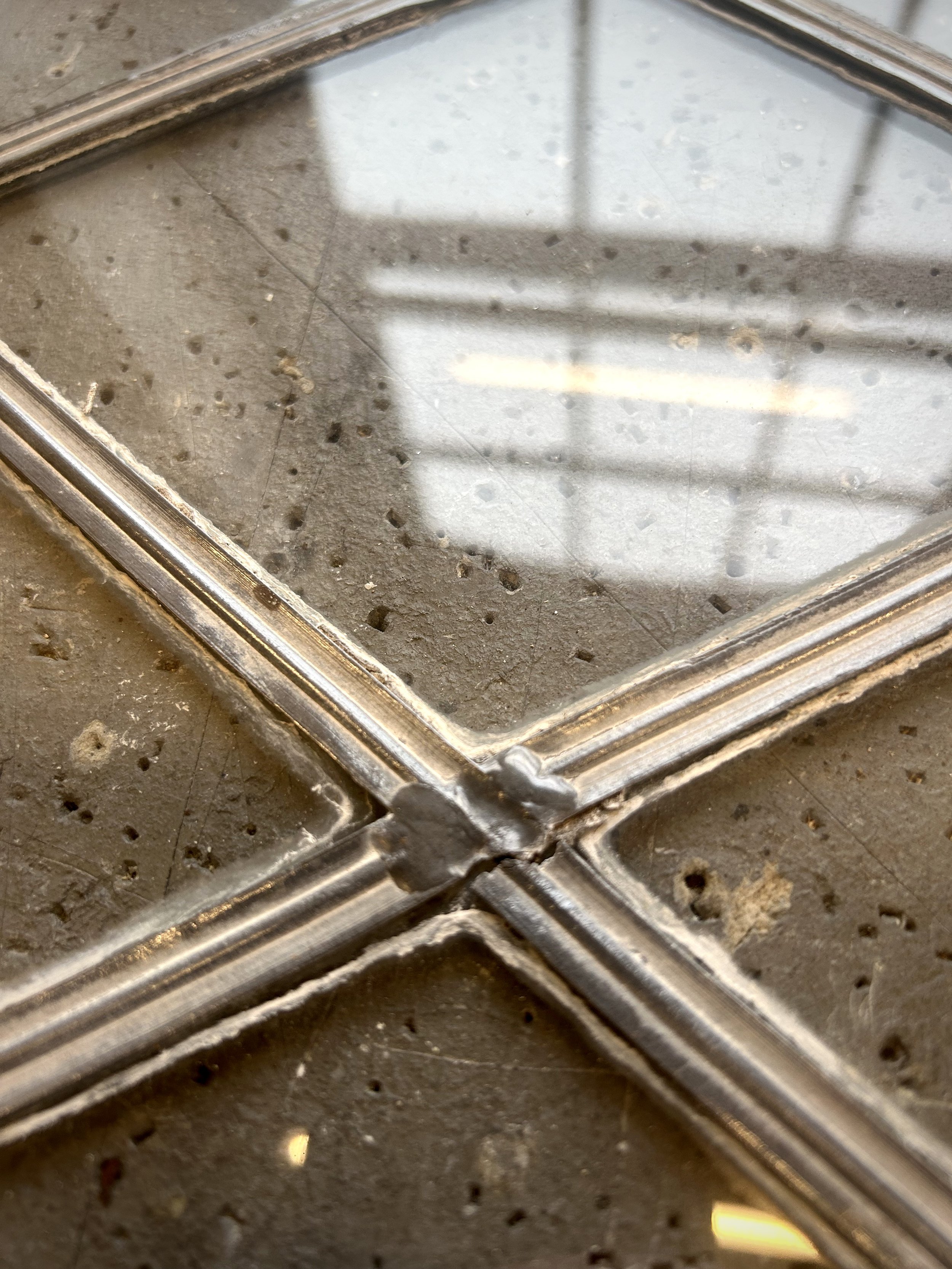

Each aspect of these windows required study and consideration, from glass matching to painting style, to releading them in a manner that honored the originals.

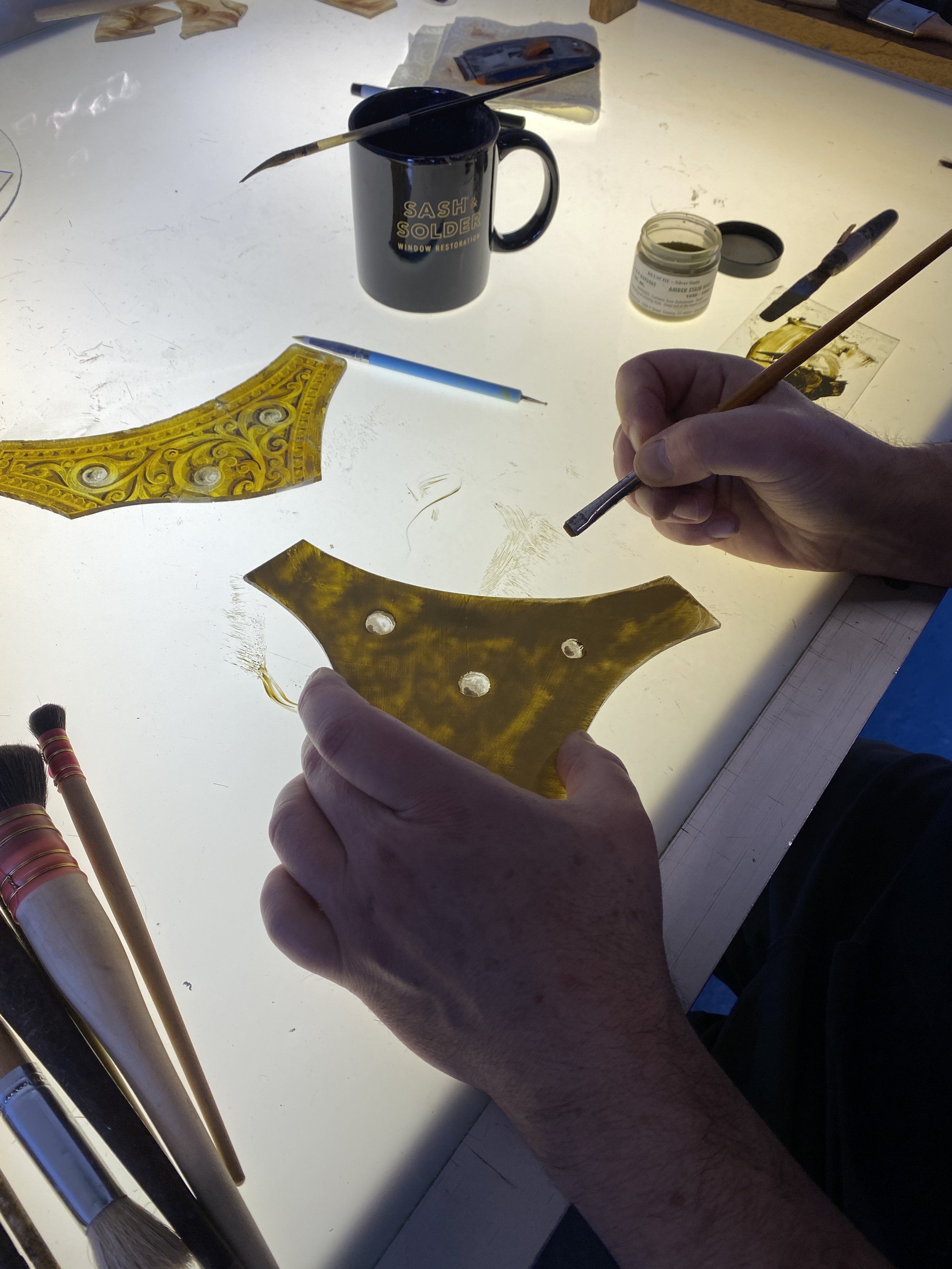

With the very limited amount of reference, we did a lot of testing; background washes, line weights, pigment colors and more. If you’ve ever painted on glass, you know it’s a finicky and fragile process — adding and removing pigment to a surface that’s not really conducive to it. Starting with the the paper sketches we did beforehand. we were able to produce faces that are very close to the original painting style.

The final four were painted on clear glass circles and then fired in our kiln. Afterwards, they were plated with etched glass circles to create a diffused and ethereal look in transmitted light, and to keep the painted elements from becoming lost in reflected light.

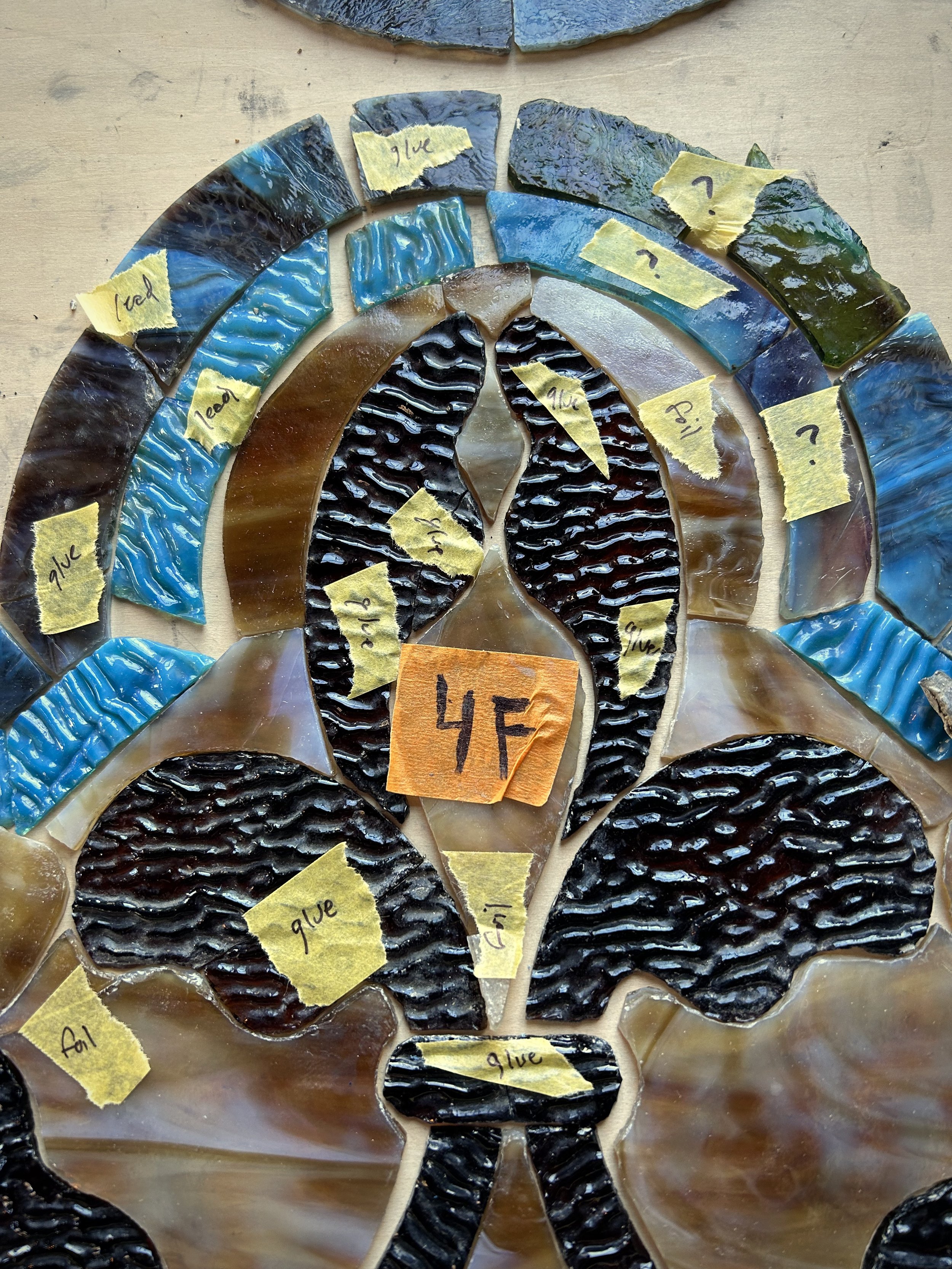

The panels have two layers of glass throughout, to match the original. Before leading, the matching layers are wrapped in copper foil tape to block putty from getting between the layers in the course of the cementing process.

On July 9th, we traveled to the chapel to install the windows. The angels had been completed and sitting in our shop for weeks, so we’d gotten used to enjoying them… But seeing them in their rightful place was a whole different experience.

They sit in a darker portion of the chapel, creating an intense effect when light beams through them. The angels’ faces change slightly based on the angle you’re viewing from, and the blue of the background can look green based on the amount of vegetation outside. The border glass is vibrant and looks great next to the new mahogany sashes. We were thrilled and relieved to see it all come together so beautifully.

We’re beyond proud of the work, especially given that each one of us contributed in a meaningful way. Dennis was the lead and coordinated many of the details, in addition to painting the faces. Patrick painted the wings. Heather painted the Maltese Cross pieces in the background. Tom and Dennis tackled the leading and Tracy brought it home by integrating the panels and prepping them for installation.

We fretted every detail along the way. But, because of that, we were able to recreate them faithfully and be part of the remarkable restoration of this beautiful place. Many thanks to the Belmont Chapel foundation for engaging us in this project!