We were commissioned to create this multi-faceted, curved, entryway transom for a newly-renovated building in downtown Portsmouth. One of our more technical design and build projects to date — this is another project where we teamed up with Michael Wise (local woodworker, manager of Woodworks, and our neighbor at the Button Factory.) He provided us with the curved wooden sash, and we went to work from there.

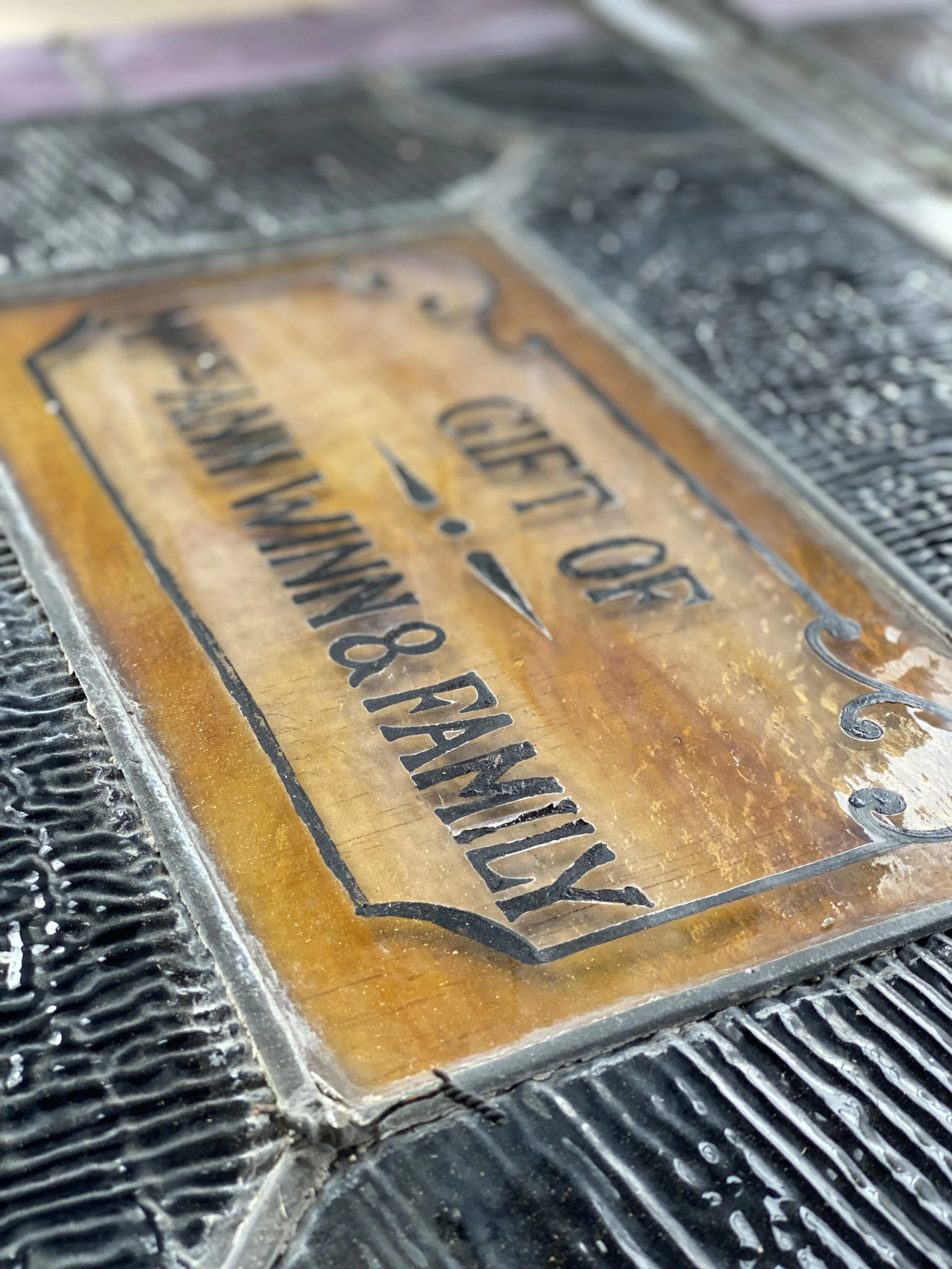

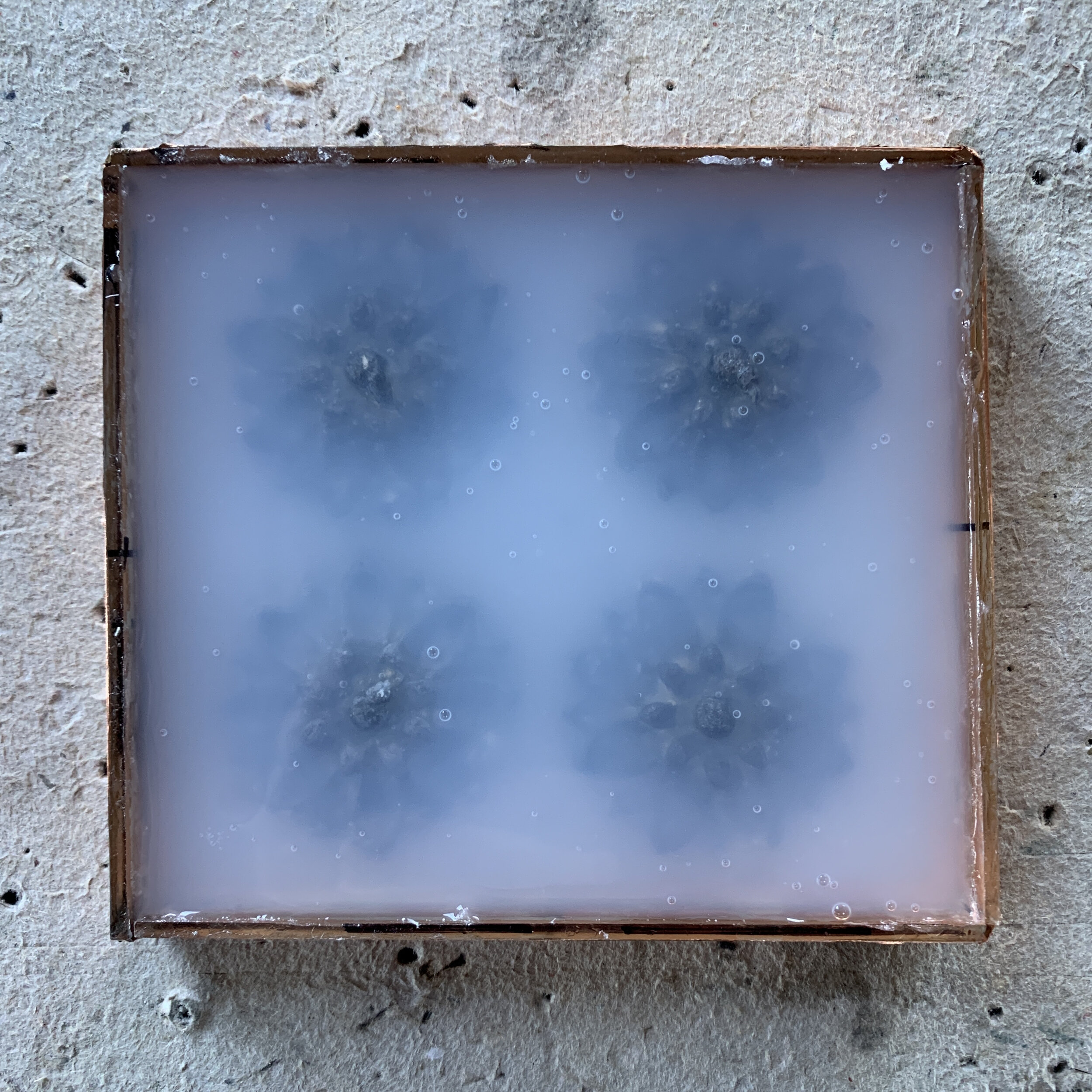

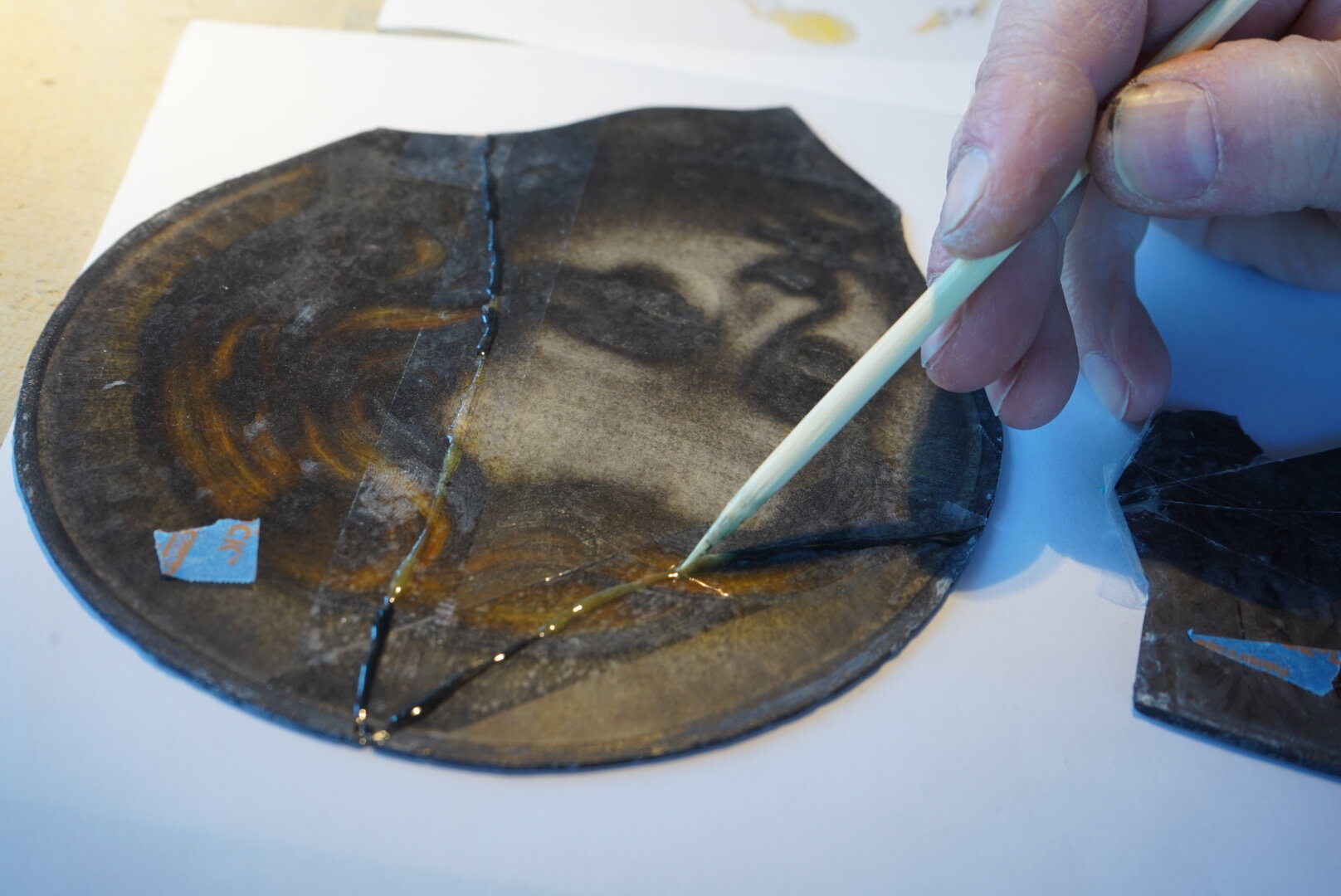

The design of the window is a direct lift from others in the historic building. Our challenge was to bend it to fit the curvature of the new entryway. Dennis created molds to slump the glass in our kiln. And once we nailed down the design for the lettering, he hand-painted the lettering, and each of the 21 pieces was fired and slumped to the proper curve.

From there, we built the window against a curved form using 3/4-inch Colonial lead and puttied it as we would any leaded window. Once cured, we installed it, and couldn’t be happier with the end product. Close to Portsmouth, NH? Come check it out near the rear entrance of Toscano Chophouse. Shoutout to Mark and the McNabb Group for being great to work with.