This was one of our ‘23-’24 winter projects. We did a full restoration of five 8’ tall doors as well as 10 very large casement windows from a home in Northeast Harbor, ME. The home is situated on a site that’s lovely, but very exposed, which means the windows naturally require more maintenance.

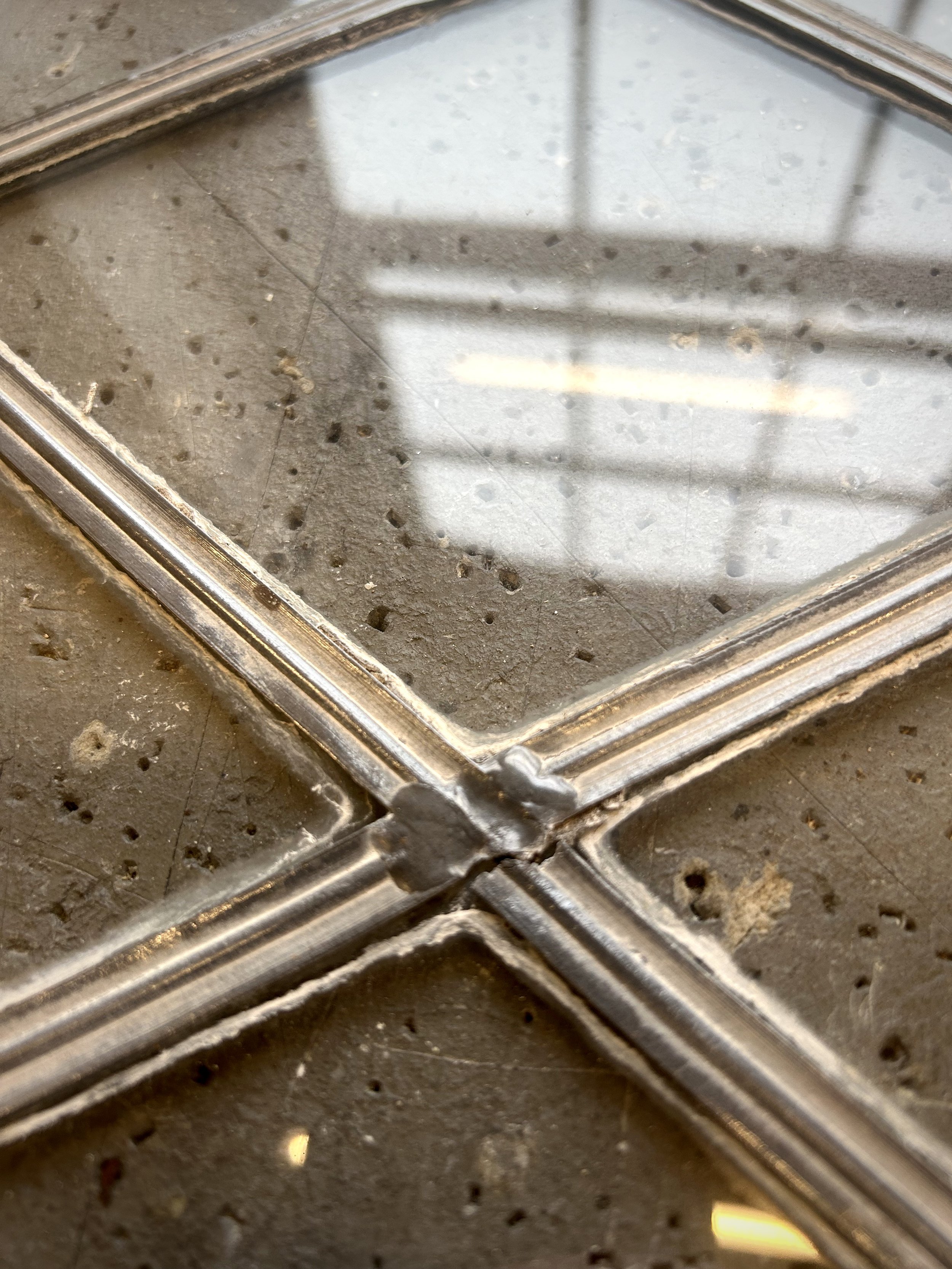

The diamonds were ready to be completely releaded. That means all the panels are disassembled, cleaned and put back together again. The majority were built with a basic flat lead, but for a portion of them, we needed a colonial style lead profile that we couldn’t source. Instead, we worked with DHD Metals to have a new dye made based on pieces of the original. They did an excellent job creating a match for us.

In the studio, Patrick devised a system wherein he pre-cut the lead came to various lengths. This gave us a great deal of efficiency once we went to build the large number of windows. As you can imagine, these panels are heavy and require a great deal of support. (Flipping the massive doors during the soldering process was no easy task!) New bars were installed on all the panels and doors, and new interlocking weatherstripping from our colleagues at Window Restoration Supply matched the original nicely.

The homeowners have worked with E.L. Shea for many years to maintain the woodwork, and as a result, the sashes and doors were in very good condition. We did just a light restoration before integrating the leaded panels. This included stripping some of the finish on the interior due to dogs scratching through the clear coat over the years. Tracy stained and finished it to match the original perfectly.

We were able to complete the work and install the windows just before Memorial Day — in time for the home to be opened up for the summer season.

Special thanks to Nate and the rest of the crew from E.L. Shea for helping us hang and tweak the doors. They were all closing perfectly by the time we left. We look forward to Phase 2 over the winter of 2024.